MINE WATER MANAGEMENT

Need Water Support for Your New Infrastructure Project?

We will be the best and easiest solution for all your industrial marine applications

MODULAR BARGES

MARINE CRUISE

CERTIFICATIONS UNDER CANADA TRANSPORT TO MOVE HEAVY LOADS ON WATER

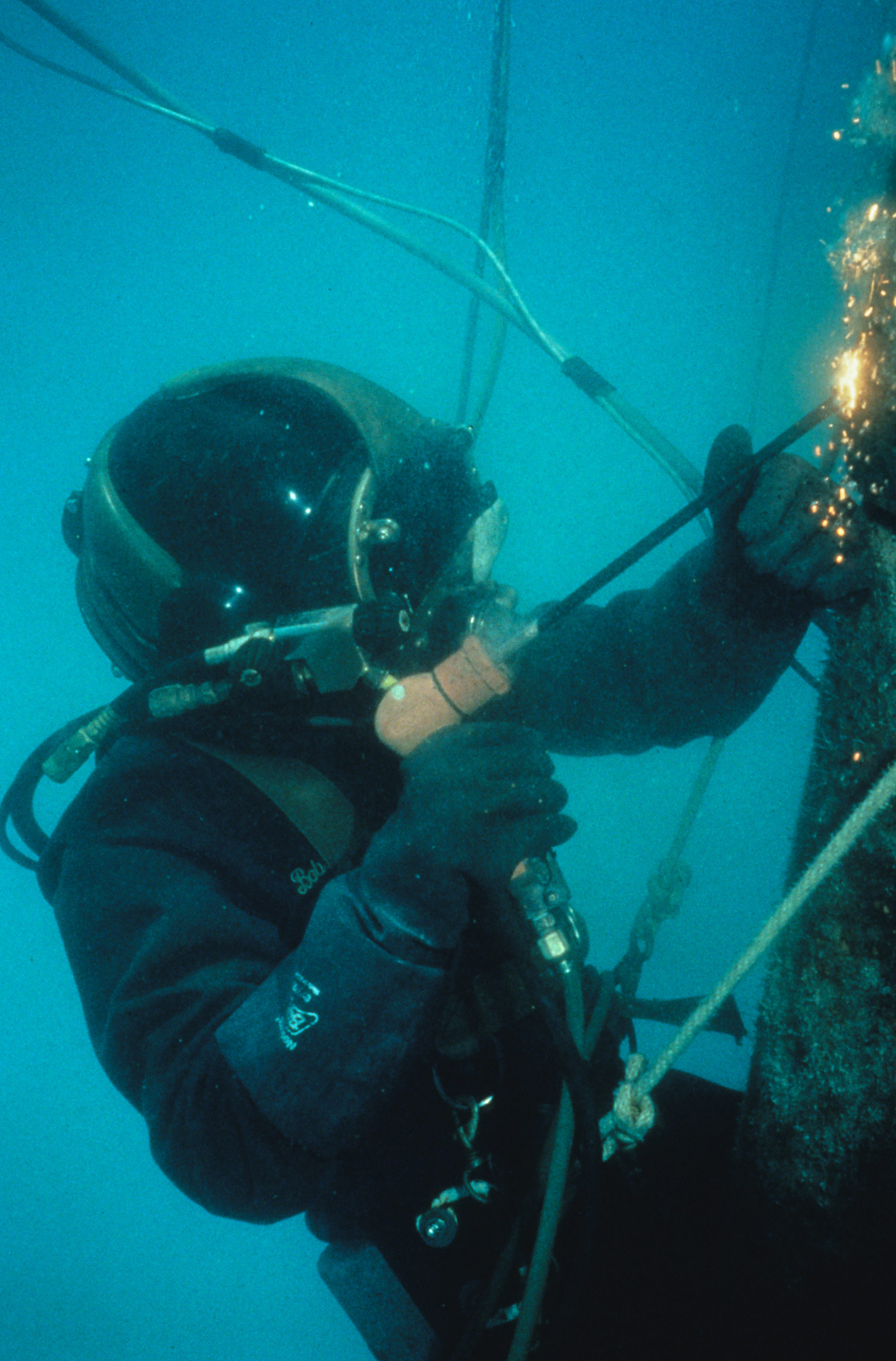

Is Your Underwater Infrastructure in Good Working Order?

We Provide:

- Underwater Inspections

- Hydrographic Surveys to Map the Area

- Certified Dive Crews

- Remotely Operated Vehicles (ROVs)

- Other Inspection Tool

MINE PROjECTS

Completed Projects

We have a team of application engineers ready to help you with all your planning needs.

TRANSFOR YOUR MINE OPERATIONS TODAY

Is Silt and Debris Filling Up Your Pumps?

We offer dredging services that can clean your pumps and service your projects so you can conduct operations smoothly.

MINE PROYECTS

Completed Projects

Concerned About Drainage, Water Runoff, or Water Transfer?

We have a fleet of surface and submersible pumps ranging from 4 inches to 24 inch, available for all applications.

(780) 922-1178

–

THE BEST AND EASIEST SOLUTION FOR ALL DIVE ● PUMP ● BARGE ● DREGE NEEDS

CLIENTS

Key Components of an Effective Mine Water Management Plan

Canada Pump and Power is a leader in providing sustainable and innovative solutions for the mining industry. With a commitment to operational excellence and environmental stewardship, our expertise spans all aspects of mine water management—from planning and design to implementation and long-term monitoring.

1. Strategic Objectives

o Operational Continuity: The primary goal is to ensure safe and uninterrupted construction activities by effectively controlling both groundwater and surface water. This minimizes water-related delays and protects excavation areas from flooding.

o Regulatory Compliance: Our plan is designed to meet all local, regional, and national water quality and discharge standards, ensuring that operations remain within the legal framework.

o Environmental Stewardship: Protecting local ecosystems and water resources is a key priority. Advanced treatment technologies and continuous monitoring are employed to ensure that water discharged from the site is free of harmful contaminants.

o Resource Optimization: Efficient water reuse strategies reduce both water procurement costs and environmental impacts by repurposing treated water for operational needs such as dust suppression and equipment washing.

2. Site Assessment and Planning

o Hydrogeological Analysis: A thorough evaluation of the groundwater flow, aquifer characteristics, and seasonal water table variations informs the design of dewatering systems. This analysis ensures that the correct combination of wellpoints, sumps, or deep wells is implemented based on site-specific conditions.

o Surface Water Considerations: Mapping local drainage patterns, precipitation data, and proximity to natural water bodies is critical. This information guides the placement of diversion channels and retention ponds to effectively manage surface runoff.

o Zoning for Dewatering: By identifying critical areas—such as open pits, trenches, and foundation excavations—the plan ensures that water management efforts are focused where they are needed most, thereby enhancing both safety and efficiency.

3. Dewatering Techniques and Infrastructure

o Groundwater Control Methods: The use of wellpoints and sumps is ideal for managing shallow groundwater, while deep wells address water control in deeper excavation zones. These systems are designed to maintain dry and safe working conditions during construction. Deep well systems may require Mineral and H2S controls.

o Surface Water Management: Temporary diversion channels are constructed to direct surface runoff away from active work areas. Additionally, retention ponds capture excess water, allowing for controlled release or on-site reuse.

o Integrated Systems: In many cases, effective water management requires the integration of both groundwater and surface water control systems. Such integrated systems ensure that water is efficiently collected, treated, and managed throughout the construction phase.

4. Water Treatment and Reuse

o Contaminant Removal: Extracted water often carries sediments, hydrocarbons, or other contaminants. Treatment processes—including sedimentation, filtration, and oil-water separation—are critical to ensuring that water meets environmental discharge standards.

o Regulated Discharge and On-Site Reuse: Once treated, water is either safely discharged into the environment (in compliance with all regulatory requirements) or repurposed for on-site activities. Reusing water for tasks like dust suppression and equipment washing not only conserves resources but also reduces overall operational costs.

5. Monitoring, Maintenance, and Adaptive Management

o Real-Time Monitoring: Installing piezometers and conducting regular water quality tests provide continuous insight into water levels and contaminant concentrations. This data enables timely adjustments and proactive management.

o GPS and Operating Condition Monitoring: The use of GPS enabled tracking systems and Equipment Monitoring Devices aid in reducing personnel intensity and increases the efficient deployment of resources.

o Preventive Maintenance: A rigorous maintenance schedule for pumps, pipelines, and treatment systems minimizes the risk of operational disruptions. Regular inspections ensure that all equipment remains in optimal working condition.

o Documentation and Reporting: Detailed records of water volumes extracted, quality test results, and maintenance activities support transparency and facilitate compliance with regulatory reporting requirements.

6. Environmental Protection and Risk Management

o Erosion and Sediment Control: Measures such as silt fences, sediment traps, and erosion control blankets are implemented to prevent sediment-laden water from reaching nearby waterways.

o Emergency Preparedness: Contingency plans are established to handle unexpected events, such as equipment failures or heavy rainfall. These plans ensure rapid response and mitigation of any potential environmental impacts.

o Long-Term Monitoring: Even after construction is complete, ongoing monitoring is essential to detect and manage any residual effects on local water systems, ensuring long-term environmental sustainability.