Simplified Troubleshooting

March 1, 2023

Should a Mighty Pump fail to prime, several simple checks can be made to isolate the problem.

Most common problems:

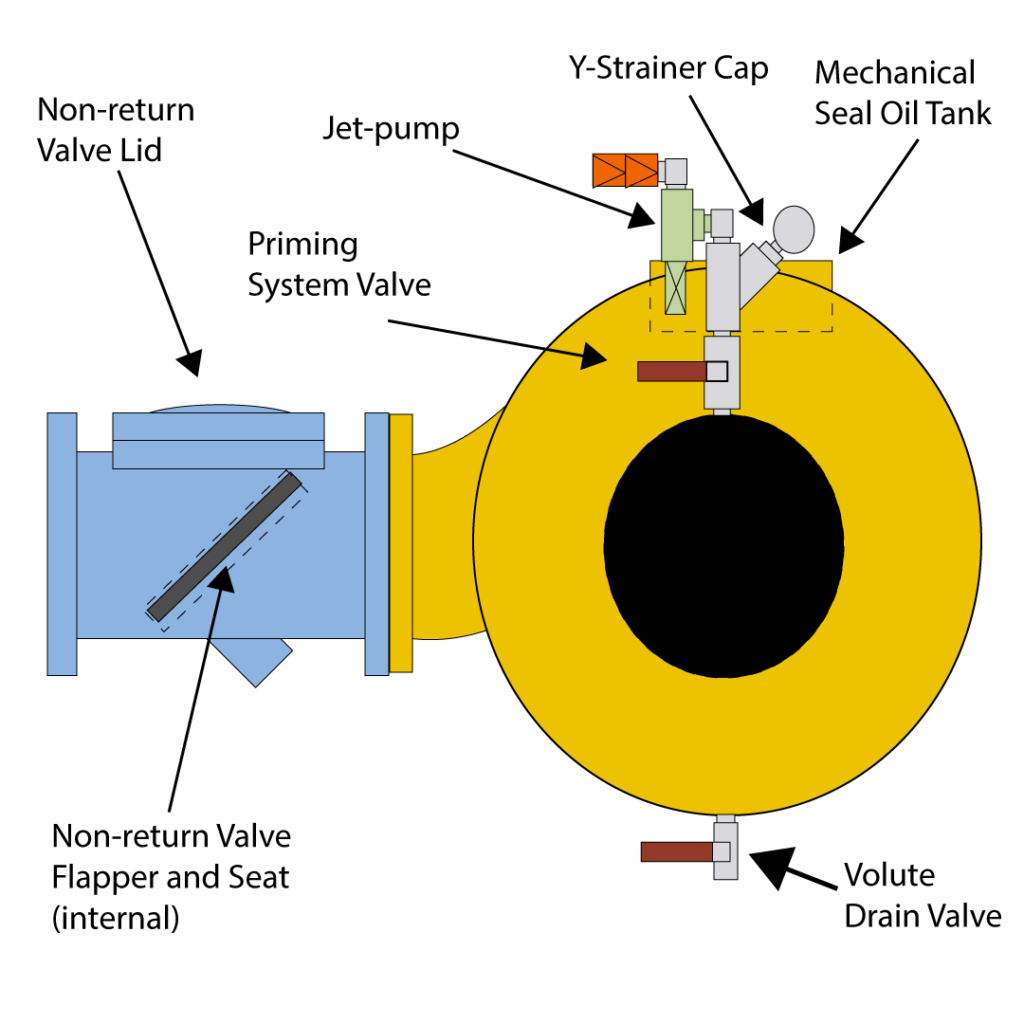

- Priming system valve is closed. A closed priming system valve will prevent air from being evacuated from the suction line. Open valve and start pump.

- Volute drain valve is open. An open drain valve will allow air into the pump. Close drain valve and start pump.

- Intake suction screen plugged. Shut down pump and open volute drain valve. Product in suction hose will “backwash” screen. Also remove intake screen from product and inspect for debris.

- Perform system check. Remove intake suction hose and place a mud flap or vacuum pad over the pump intake to test priming system suction. Suction will register on the gauge mounted on the Y-strainer cap.

If there IS priming suction (perform steps 5-6)

- Intake suction hose leak. Check for missing or cut gaskets in joints or cuts in the suction hose.

- Vertical suction distance too high. Move pump closer to the product surface level. Remember that increased altitude reduces suction lift.

If there IS NOT priming suction (perform steps 7-10)

- Air leaking into the pump through drain valve. Remove drain valve top lid or disconnect outlet hose from the drain valve. Inspect flapper and seat for damage or debris. Clean and reassemble.

- Priming system screen is plugged. Remove the Y-strainer cap to access the priming system screen. Remove screen and clean. Replace screen and reassemble.

- Mechanical seal oil leak. Ensure that mechanical seal oil tank has sufficient oil reserve. Check back of pump for leaking mechanical seal oil drips or puddles. Contact Mighty Pumps for service.

- Jet-pump blocked or air compressor failure. Check priming system discharge hose for blowing air. Little or no air flow indicates a blockage or failure. Contact Mighty Pumps for servicing.